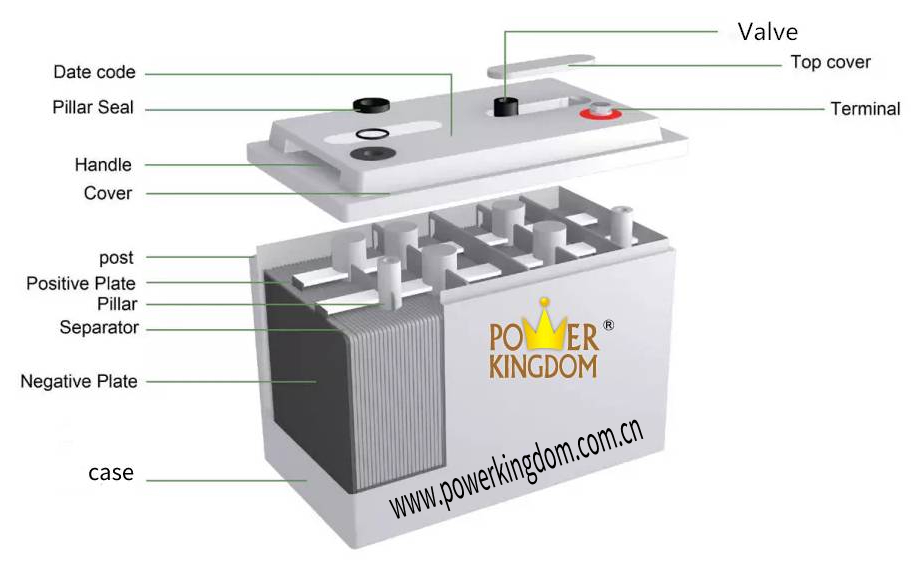

lead-acid batteries are one of the earliest types of rechargeable batteries. They are the most widely used rechargeable battery.They are used in back-up power supplies for alarm and smaller computer systems (particularly in uninterruptible power supplies, UPS) and for electric scooters, electric wheelchairs, electrified bicycles, marine applications, electric vehicles or micro hybrid vehicles, motorcycles and Wind, solar ,renewable energy storage system.The lead acid battery construction is illustrated below.

Positive Plate:

positive plates are plate electrodes of which a grid frame of lead-tin-calcium alloy holds porous lead dioxide as the active material

Negative Plate:

negative plates are plate electrodes of which a grid frame of lead-tin-calcium alloy holds spongy lead as the active material

Separators:

Power Kingdom lead acid battery separators, which retain electrodes and prevent shorting between positive and negative plates adopt a nonwoven fabric of fine glass fibers that is chemically stable in the diluted sulfuric acid electrolyte. Being highly porous, separators retain electrolyte for the reaction of active materials in the plates.

Valve(one way valve):

The valve is comprised of a one way valve made of material such as neoprene. When gas is generated in the battery under extreme overcharge consideration due to erroneous charging,charger malfunctions or other abnormalities,the vent valve opens to release excessive percific rang(5 to 45 kpa ). During ordinary use of the battery, the vent valve is closed to shut out outside air and prevent oxygen in the air from reacting with the active material in the negative electrodes.

Positive and negative terminals:

Positive and negative electrode terminals may be fasten tab type, bolt fastening type, threaded post type, or lead wire type, depending on the type of the battery. Sealing of the terminal is achieved by a structure which secures long adhesive-embedded paths and by the adoption of strong epoxy adhesives.

Battery case:

Material of the body and cover of the battery case are manufactured from ABS resins, unless otherwise specified.

Power Kingdom brand battery has been promoting in the international market since 2002. As a VRLA battery manufacturer and supplier, we have developed one of the most comprehensive battery ranges within the industry. Our factory acquired with ISO9001, ISO14001 and also honored with UL, CE, VdS certificate. All Power Kingdom batteries comply with international standards. We also provides OEM or custom battery solutions for our clients.

We are here to help you! If you close the chatbox, you will automatically receive a response from us via email. Please be sure to leave your contact details so that we can better assist